Semiconductor Production Line Retrofit

Thanks to the targets set by the authorities in Europe and France, the semiconductor production sector is undergoing major change. To become independent again in terms of semiconductor manufacturing, production is becoming localised and industries need to increase their productivity.

They need to acquire a more efficient and productive production line. Hence the interest in retrofitting semiconductor production lines.

Why is more Localised Production of Semiconductors Important?

A number of sectors that use electronic chips are facing a shortage of semiconductors. The automotive industry, one of the biggest consumers of semiconductors, is one of the sectors that has suffered most. As a result, the production of electronic chips is having to be relocated.

According to figures published by the Boston Consulting Group and the Semiconductor Industry Association, Japan, the United States and Europe were the major semiconductor producers in 1990, with market shares of 20%, 37% and 40% respectively. But the picture has changed. All three countries have reduced their production following the arrival of Taiwan, China and South Korea in the semiconductor manufacturing sector. For Europe in particular, this has left it with a market share of just 9% in 2020.

To reverse this trend, Europe has set itself the goal of localising semiconductor production. The authorities have announced a plan to develop the production of new-generation electronic chips. The pandemic crisis, which caused a problem in the semiconductor supply chain, showed the extent to which European and French industries are dependent on Taiwanese and Chinese electronic chips. For this reason, France is committed to investing in this area in order to make the country more independent and restore its sovereignty in the production of electronic chips.

This mainly involves increasing the productivity of the semiconductor industries. Not only do they need to equip themselves with new semiconductor production machines, but they also need to optimise existing solutions in order to become more productive and competitive. They can also retrofit semiconductor production lines.

Semicon Fab Retrofit and Refurbishment is Essential

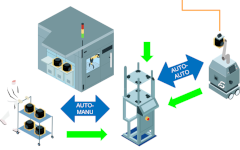

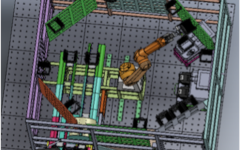

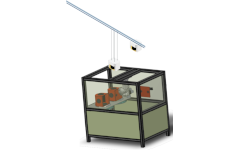

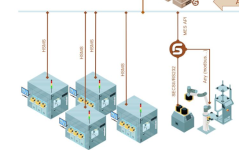

The semicon fab field is constantly evolving. If the machines you are currently using no longer enable you to achieve your objectives and are no longer able to meet your customers’ expectations, call on ATG Technologies. With semicon’s production line retrofit solutions, we can solve your problems related to the efficiency and profitability of your 200mm and 300mm lines. Our team of technical experts can upgrade your semiconductor production machines with the latest cutting-edge technologies (autonomous robotics, 5G, etc.) for enhanced performance and new integrated functionalities. By opting for semiconductor fab retrofitting, you can extend the lifespan of your industrial machines.

To retrofit your fab semiconductor solutions, our engineers focus on 3 key stages: design, modification and integration. By assessing your needs, we co-create and transform your machines so that they can offer you new, tailor-made functionalities.

ATG Technologies – Designer and Manufacturer for the Semiconductor Industry

ATG Technologies is your partner for semiconductor production line retrofits. Our 20 years of experience in the design, manufacture and integration of robotic solutions for the semiconductor industry enable us to offer you high-performance, made-to-measure machines. Thanks to our retrofit solutions, you can considerably extend the lifespan of your production equipment.

If you have any questions, please contact us using the form below. Our experts will provide you with personalised answers.

Get a free no obligation quote

Contact our sales team for a personalized quote.