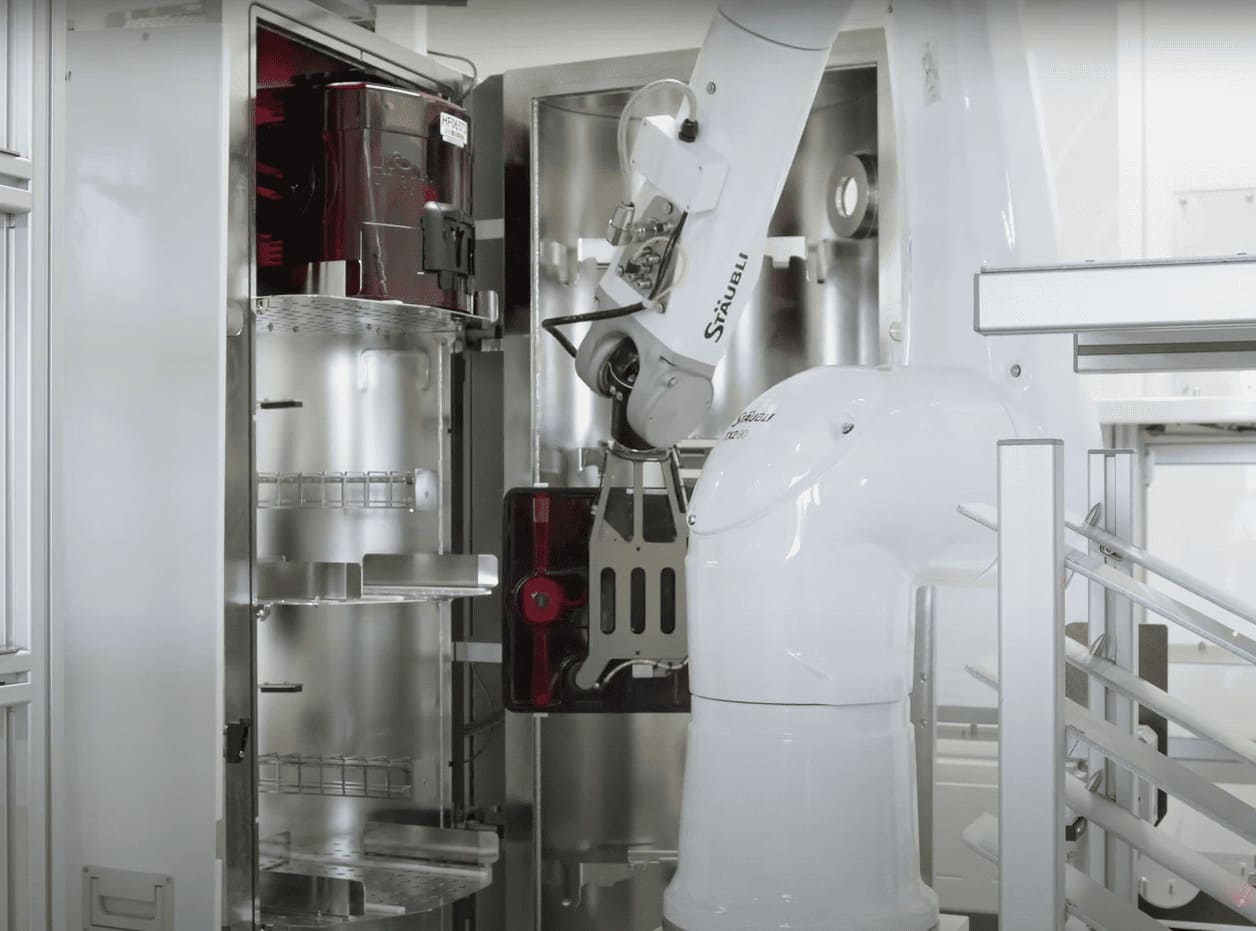

H-DEC – FOUP Cleaning System

H-DEC – FOUP Cleaning System

A FOUP (Front Opening Unified Pod or Front Opening Universal Pod) is a highly specialized plastic enclosure developed to securely store silicon wafers in a controlled environment. These pods facilitate the safe transfer of wafers between processing or measurement equipment during semiconductor manufacturing.

The FOUP cleaner by ATG Technologies plays a critical role in improving yield by addressing potential contamination issues. By implementing ATG Technologies’ FOUP solutions,you can achieve superior cleanliness standards and optimize your production yield.

H-DEC - FOUP and FOSB Cleaner

Technical Specifications

Product Features – Batch preparation up to 4 FOUPS:

- HAUD Oven Loading Cell

- Foup Opeening:Door unlock

- Doors and boxes Buffer Shelves:

- Wafer in foup control: Laser detection

- Precise robot movement

- Oven door piloting: automatic opening and closing

- Oven loading FOUP boxes / doors

- FOUP unloaded on 2 OHT load ports or on manual load port

High througput

Fully Connected

Low Footprint

High Ergonomics

ATG Technologies

Entering Industry 4.0

Engineering solutions for the semiconductor fab

H-DEC - FOUP and FOSB Cleaner

Benefits

Key benefits of FOUP cleaning solution By ATG Technologies include:

- Particle Removal: Eliminates particulates that could compromise wafer integrity.

- Humidity Reduction: Mitigates the risk of moisture-related defects.

- AMC Reduction: Decreases airborne molecular contaminants (AMCs).

- Low Cross-Contamination: Minimizes the transfer of contaminants between wafers.