Based in Avignon in the beautiful Provence region, ATG Technologies industrial premises comprise a 400 sqm workshop, 300 sqm of office space and a 50 sqm clean room for the most demanding of applications. The technical team develops collaborative industrial robotic solutions including cutting edge technologies.

Thanks to the relevance of its developments and its close relations with leading-edge sectors such as microelectronics, ATG Technologies has always known how to adapt its equipment design to meet the needs of every industrial era it has been through, always integrating breakthrough technologies within its equipment.

At the end of 2018, ATG Technologies took a strategic decision to consolidate its position in the semiconductor field. First through the acquisition of ATG Technologies by Hervé de Malliard, president of Lyon-based MGA Technologies, who will place Philippe Baldet, a specialist in industrial process automation and the current director of ATG Technologies, at the head. Then, with the recent acquisition of FOCUSSIA, a company specialized in communicating machines and the development of software interfaces with automation or ERP, MGA Technologies, through its Avignon subsidiary, has since positioned itself as the essential partner in the automation of the semiconductor manufacturing industry.

At the end of 2020, the group began a unique approach to Industry 4.0, through its MGA Tech Lab 4.0.

Early 2021, MGA Technologies integrated FOCUSSIA, a company specialized in communicating machines and the development of software interfaces with automation or ERP. MGA Technologies, through ATG Technologies, its Avignon subsidiary, has established itself as the essential partner in the automation of the semiconductor manufacturing industry.

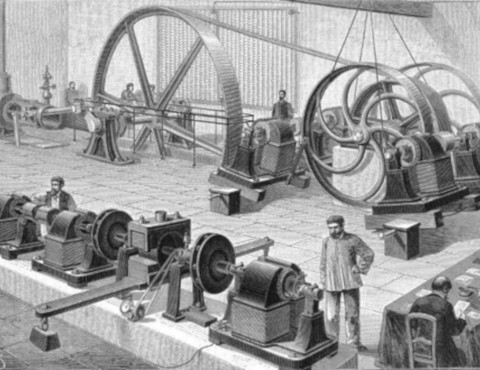

Industry 1.0 - Mechanization

Industry 1.0 is a process of development and generalization of machines. Mechanization is at the heart of the industrialization phenomenon, insofar as it profoundly modifies production methods, notably productivity, division and work rhythms.

Industry 2.0 - Electrification

Since the beginning of the industrial revolution, machines in textile or metallurgical factories have been set in motion by cumbersome, noisy and dangerous systems of belts and pulleys, which connect these machines to steam engines or gas engines. The electrical supply of each machine appeared very early as a much better solution but it implied important investments, a reorganization of the working spaces and new skills.

Industry 3.0 - Automation

Industrial automation is the art of using machines to reduce the worker's workload while improving productivity and quality. It involves electronic systems that encompass the entire control hierarchy from sensors, PLCs, communication buses, visualization, archiving to production and enterprise resource management.

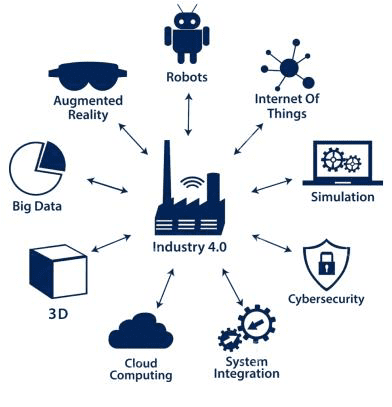

Industry 4.0 - Digitalization

Digital technology is transforming companies by changing their processes, their organization and their relationships with their customers and suppliers. This "industry of the future" accelerates the modernization of production thanks to a high level of automation and digital integration of the entire production chain. Combining the latest technological advances - robotization, horizontal and vertical integration systems, cloud computing, big data and cybersecurity - the industry of the future consists of more flexible and agile units. However, this transformation requires companies to adapt, demanding major investments in modernization and training the workforce to handle these new tools.

A real technological sandbox, a workshop occupied by a dozen employees was created in March 2021. They explore daily the robustness and relevance of emerging technologies and implement the most promising in Proof Of Concept mimicking applications of our flagship customers in the BioPharma and Semiconductor industries.

A pioneer in the construction of more efficient machines taking the place of humans at the beginning of its history, ATG Technologies has reviewed its design principles and its organization to be able to now propose communicating machines, more intelligent due to the embedded technologies and which removes the drudgery for the operators while working in close collaboration with them.